Machineseries for gas cylinders

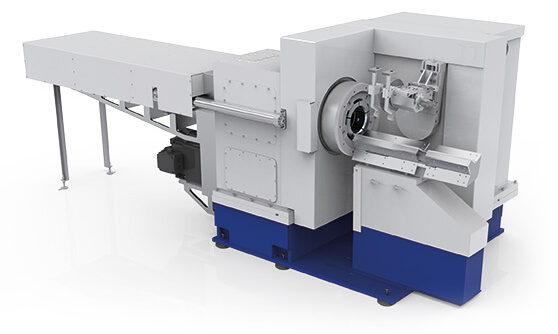

WF necking-in machine

The machineseries SFM necking-in machine closes the ends of cylindrical tubes totally and assures gas-tightness. WF Maschinenbau‘s unique technology makes it possible to produce almost any contours in the shoulder/neck area.

We manufacture machines for pressure vessels: production of ultra-small cylinders (for the beverages industry and for airbag cartridges, for example) just as much as for large cylinders (for jumbo cylinders, for instance). So now there is nothing preventing series production of your individual gas cylinders on only a single machine!

Benefits necking-in machine SFM:

- Series production of bottle bases or necks on just one machine.

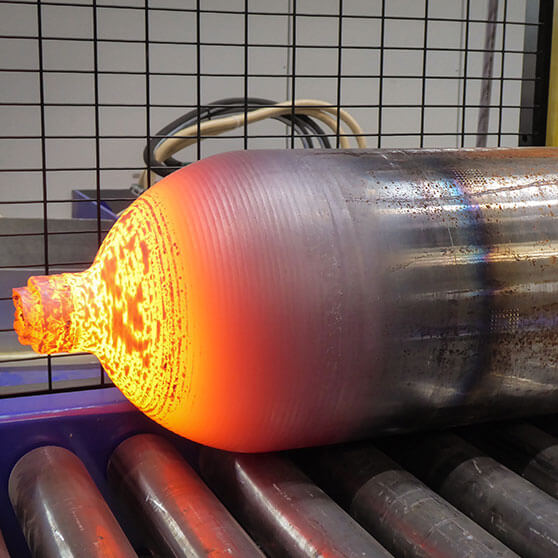

- Gas tightness with one firing operation.

- Increase of wall thickness up to 5 times the initial wall thickness.

- Flexible design of contours in base, shoulder and neck.