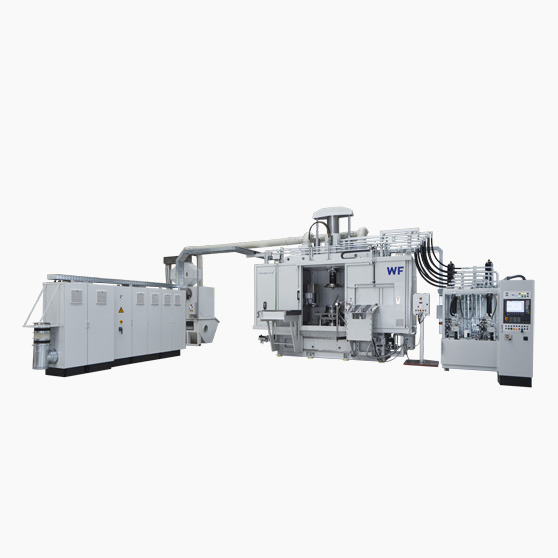

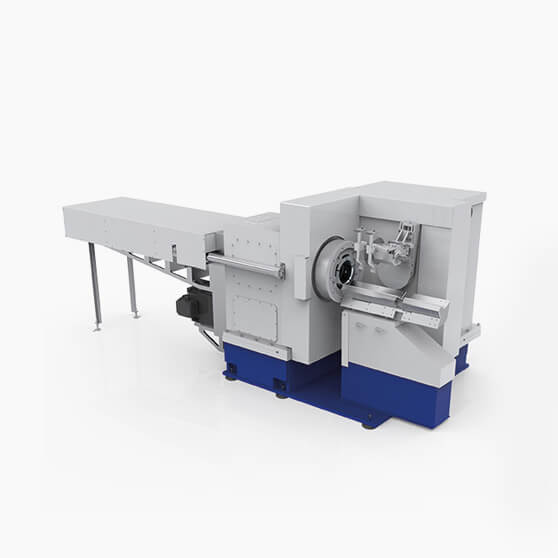

Our machines – made in Germany

Metal forming at the highest level.

We build machines for chipless metal-forming. We place the highest value on quality and durability. We rely on German suppliers who have been supplying us with materials of the same high quality for many years. This way we can ensure that our delivered machines meet our requirements. Of course, the entire production is also carried out exclusively in Germany. Therefore, we have been labeling our machines “made in Germany” for many years.

To ensure that our metal forming machines not only run perfectly mechanically, but also function optimally at the cutting edge, we live the digital transformation and thus significantly increase the productivity of our customers. With the help of our SMART FORMING tools, our metal forming machines are digitally networked and the entire production process is optimized.