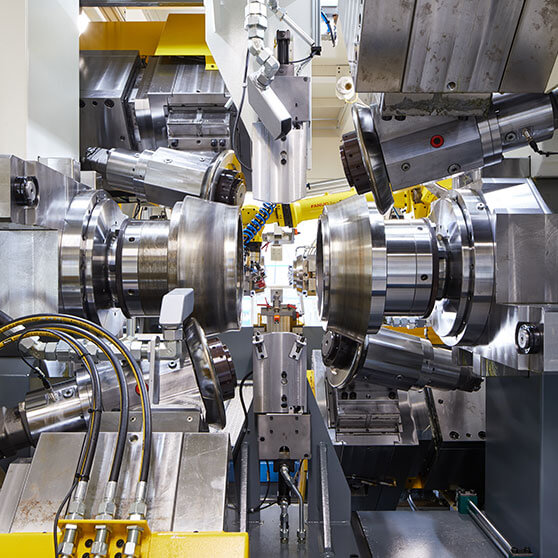

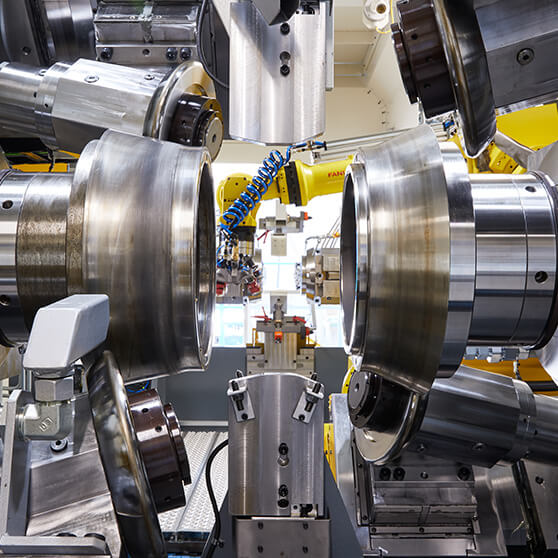

Machine series for wheel rims

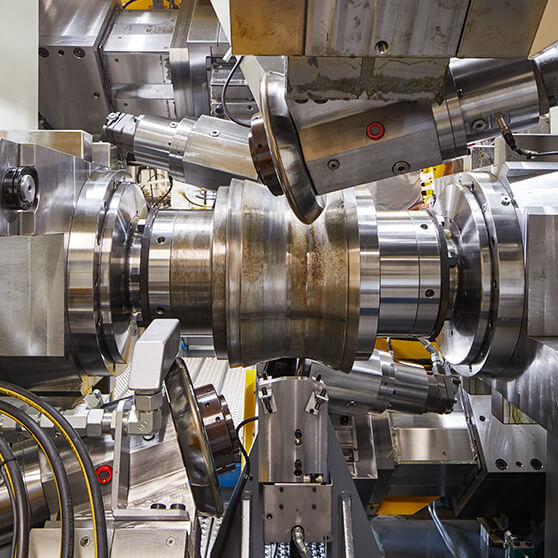

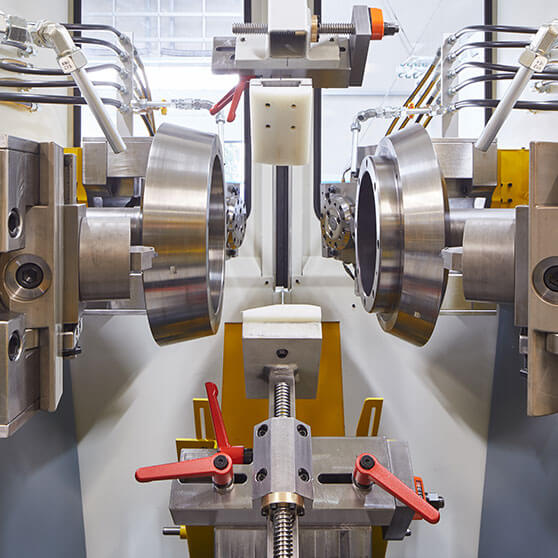

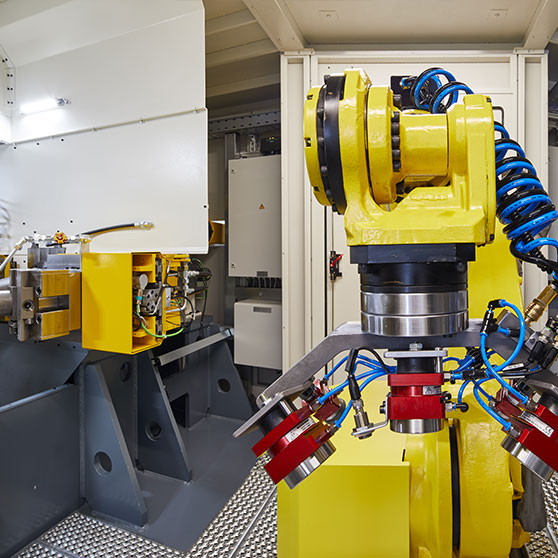

Ring flow forming center

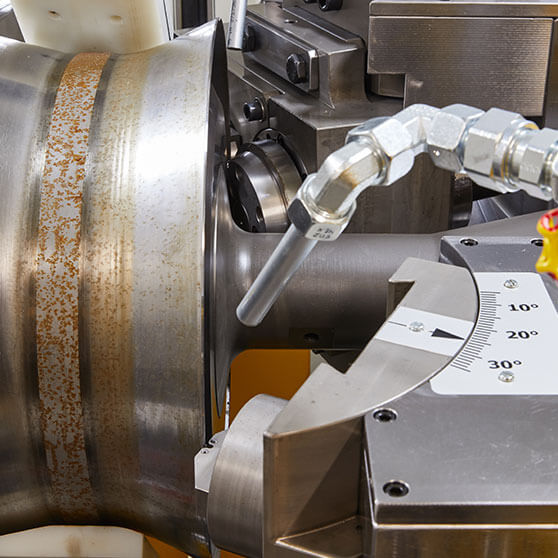

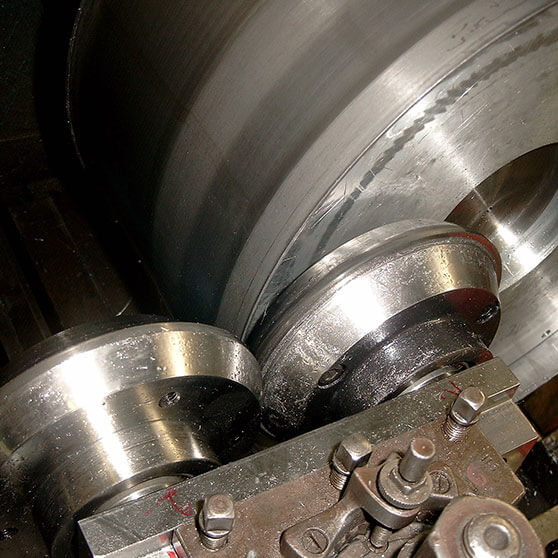

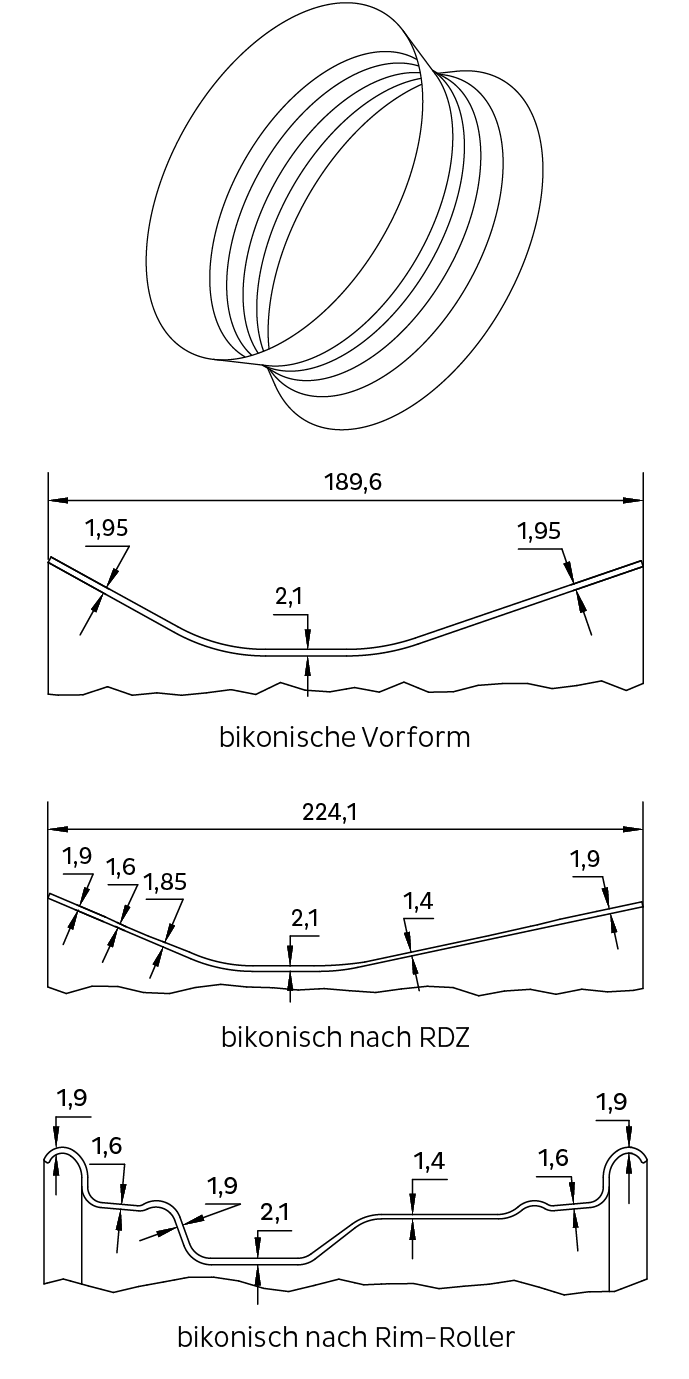

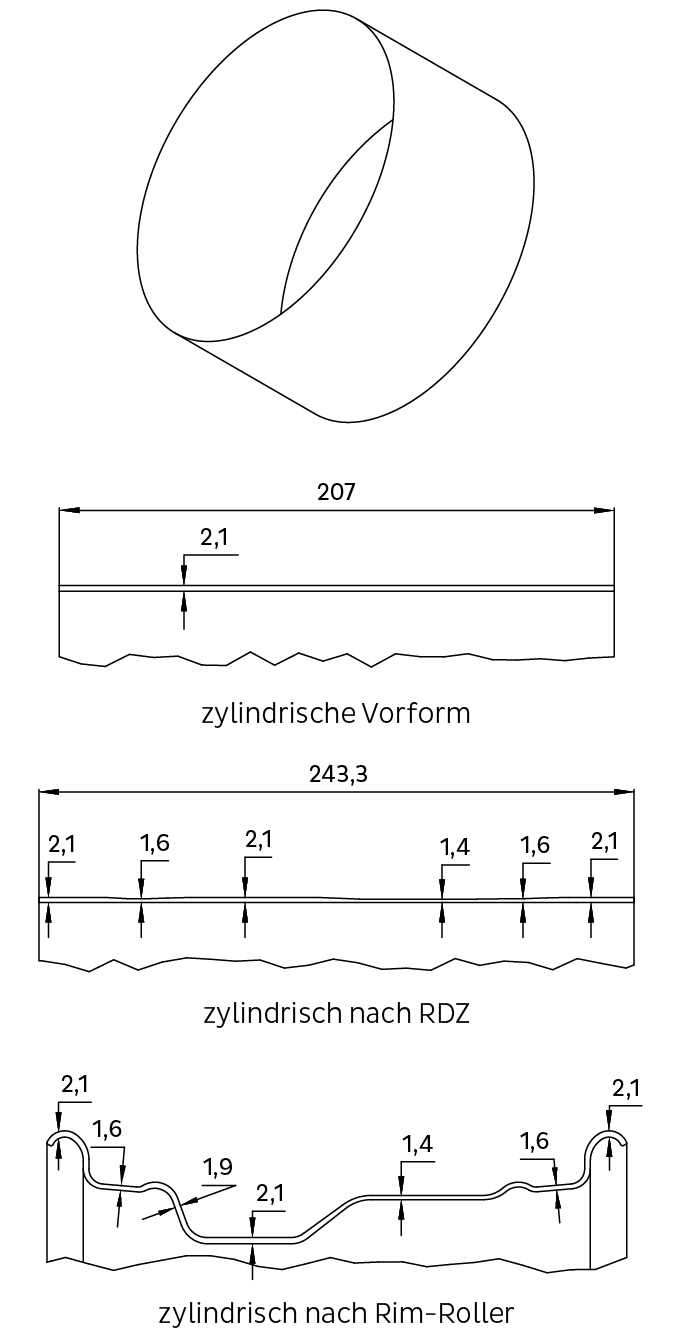

Our ring flow forming center for steel wheel rims produces preforms for wheel rims for weight-optimised steel car hubs.

The benefits of our ring flow forming center:

- Wheel-rim weight reduction of up to 25%.

- Extremely high production rates of 300 rings/hour.

- Enhanced strength despite partial reduction of wall thicknesses.

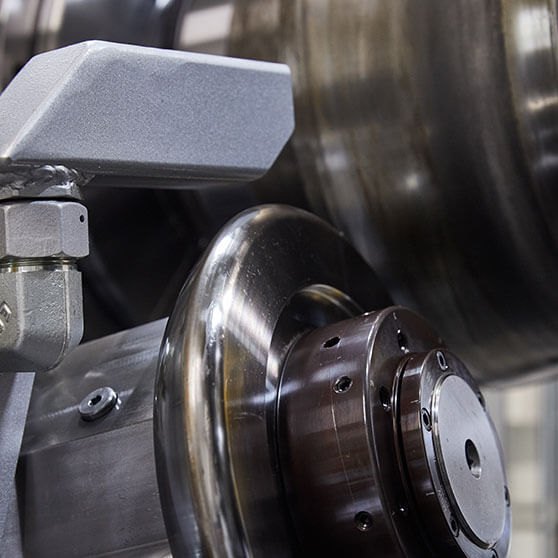

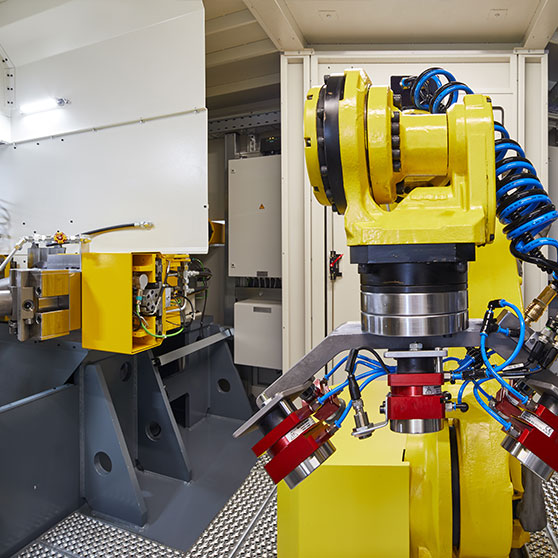

The ring flow forming center RDZ consists of a pair of machines: Flow forming plus trimming machine. It is built either in vertical (VRDZ) or horizontal design (HRDZ).