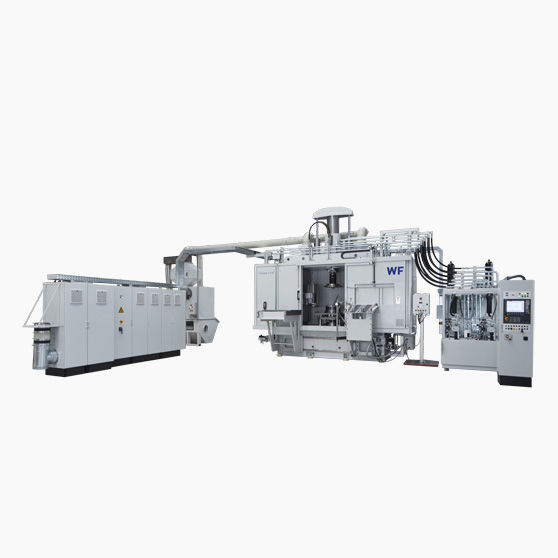

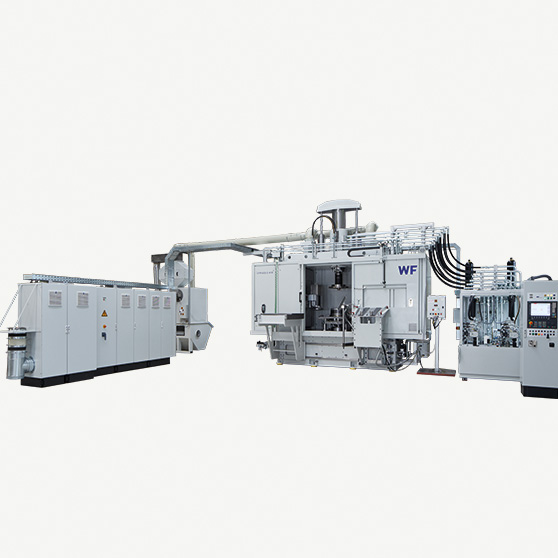

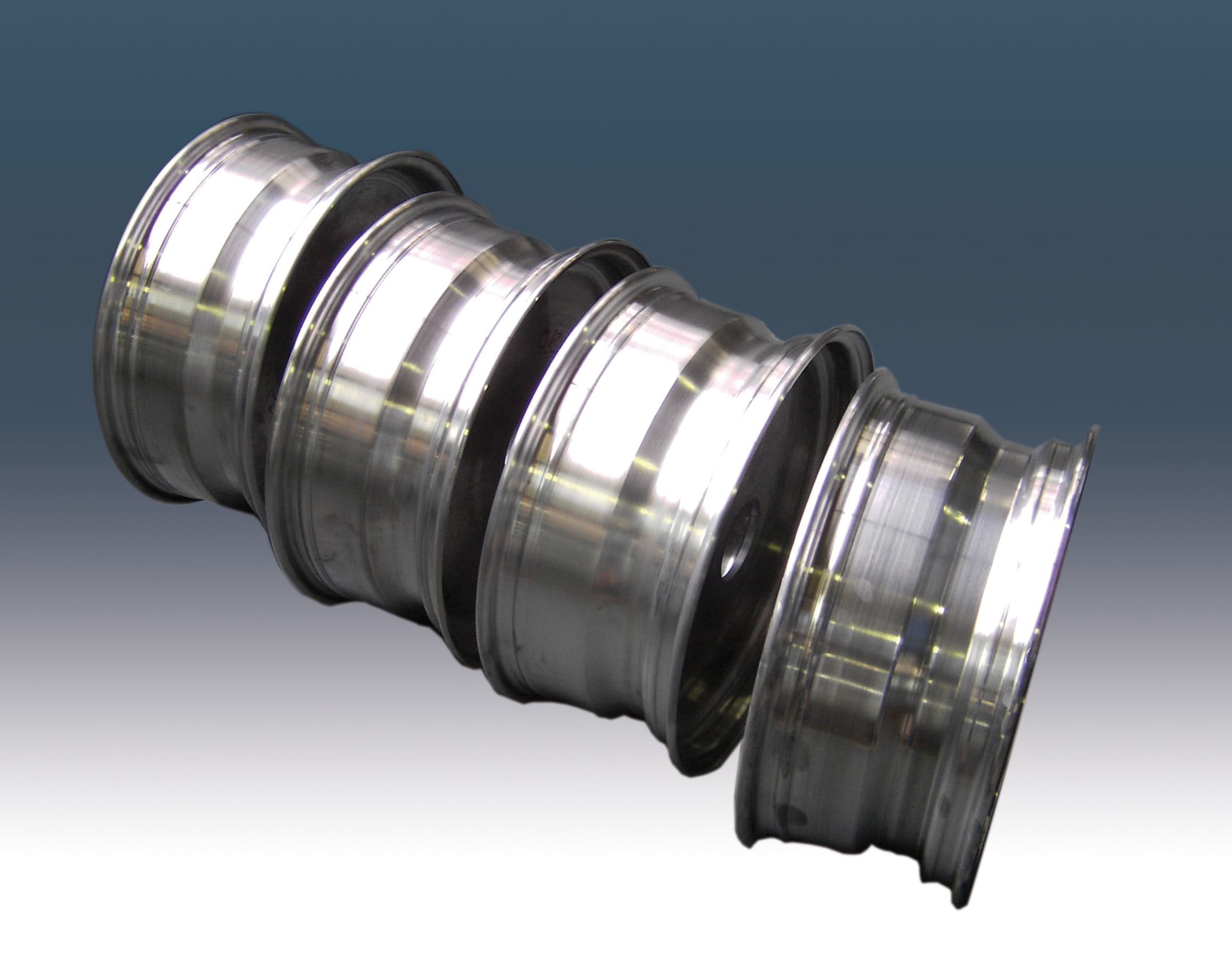

Rim making machines:

series for aluminum rings

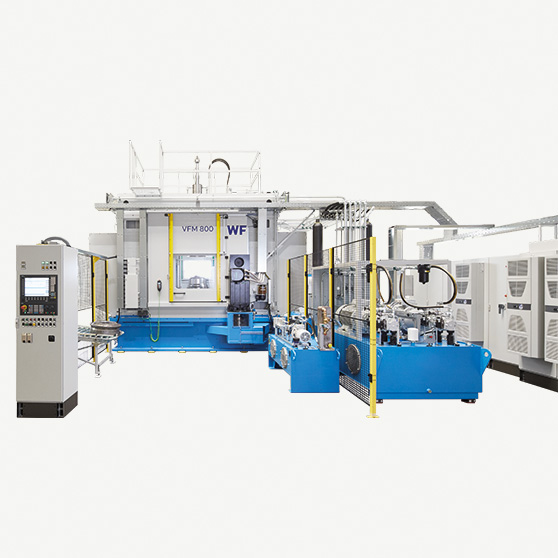

Vertical rim machines

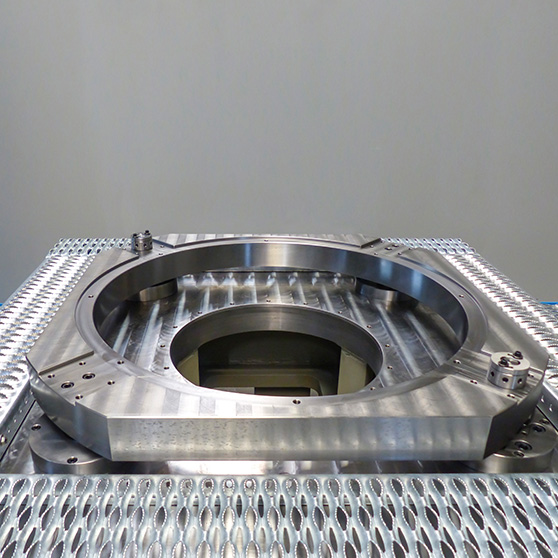

The rim machine VFM is the all-rounder for one-piece aluminum wheels. These vertical rim-making machines produce with extreme speed. Aluminum hubs up to 20% lighter (compared to wheels manufactured using other processes).

Using the rim-making machine, these are the results:

- the end-product possesses 15% greater tensile strength for the hub

- an increase of 200% in elongation at fracture

- reduced fuel consumption and lower CO2 emissions with an increased payload

- minimized production time due to single-robot feeding.

We currently offer four machine types for cold or hot forming with workpiece diameters up to max. 800mm. Further wheel-making machines you can find at the site machine-overview (Link).