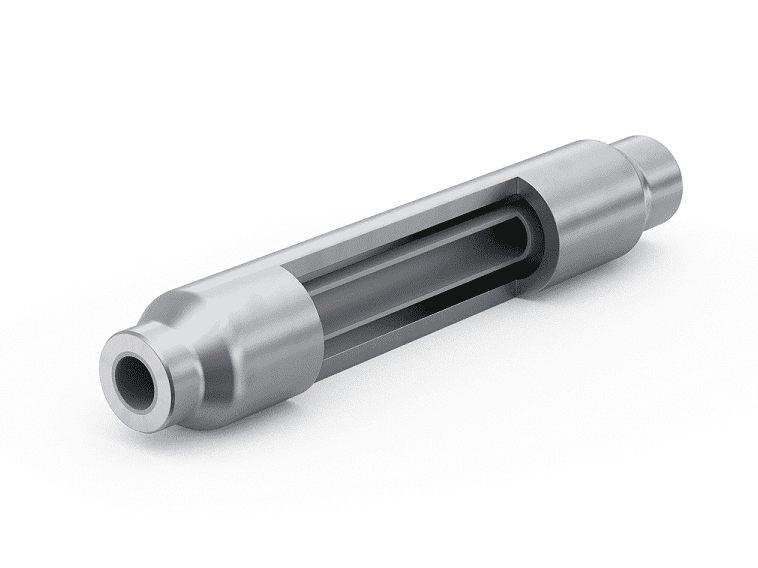

Cooling jackets

Cooling jackets for electric motors

Cooling jackets for electric motors in e-vehicles are the “enclosures”, which are installed around the stator carrier of the motor. Due to the large amount of heat generated, the stator needs to be cooled, and this is the reason that water flows continuously through the cooling jacket. Maximum possible cooling effect is achieved thanks to the surface-area-enhancing fins incorporated into the cooling-jackets.

These fins cannot be produced using a conventional flow forming process. Together with one of its customers, WF Maschinenbau has, however, developed a process which makes their production possible. It is now possible, for the first time ever, to roll a tube from the inside to the outside on a roller head. The preform flows during this process into an external finned die – and the required cooling fins are produced.

WF cooling jackets

- Forming of a one-piece cooling jacket featuring external fins in a single flow forming operation

- Zero-weld end product

- No complex and expensive milling to create cooling fins

- Diverse cooling-surface geometries possible

- Processing of aluminium and stainless steel (chromium-nickel alloy/VA) as feed