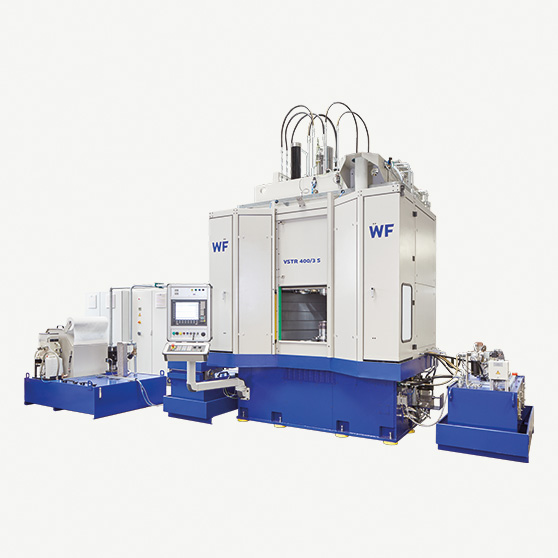

Series for precision tubes & gearing components

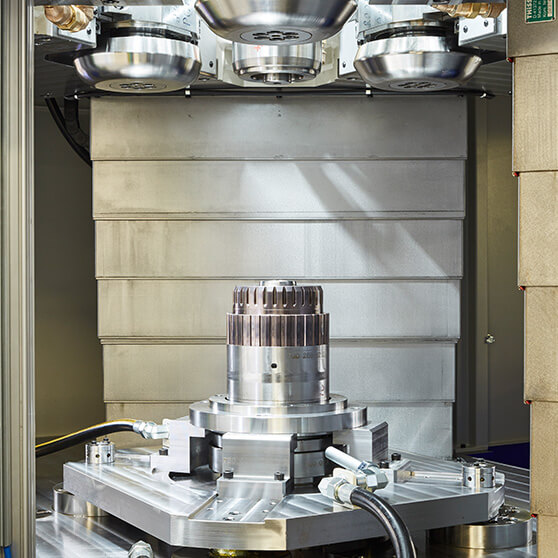

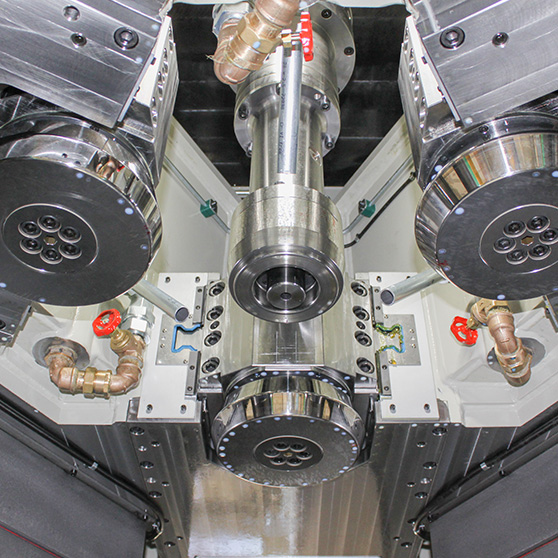

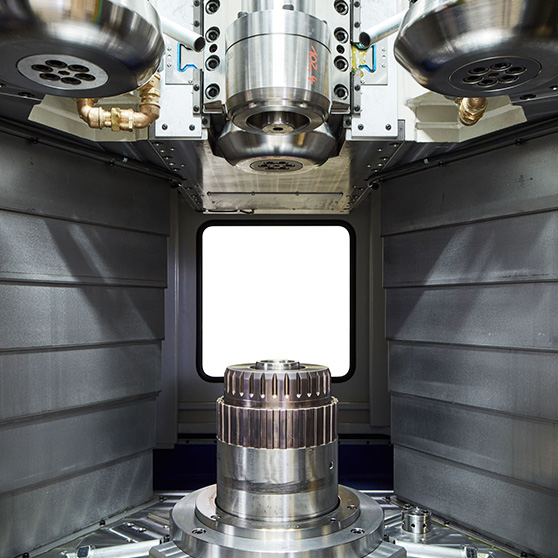

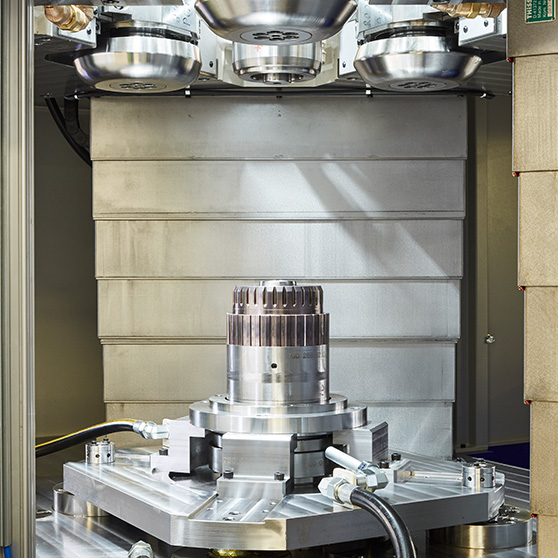

Vertical flow forming machine

Lightweight gearing components permit the reduction of fuel consumption and downstream emissions during vehicle operation. Our VSTR 400 series produces lightweighting elements that consume less material but nonetheless assure higher strength compared to chip-removing methods. It has no difficulty with components previously not feasible. And all in a compact machine with short cycle times.

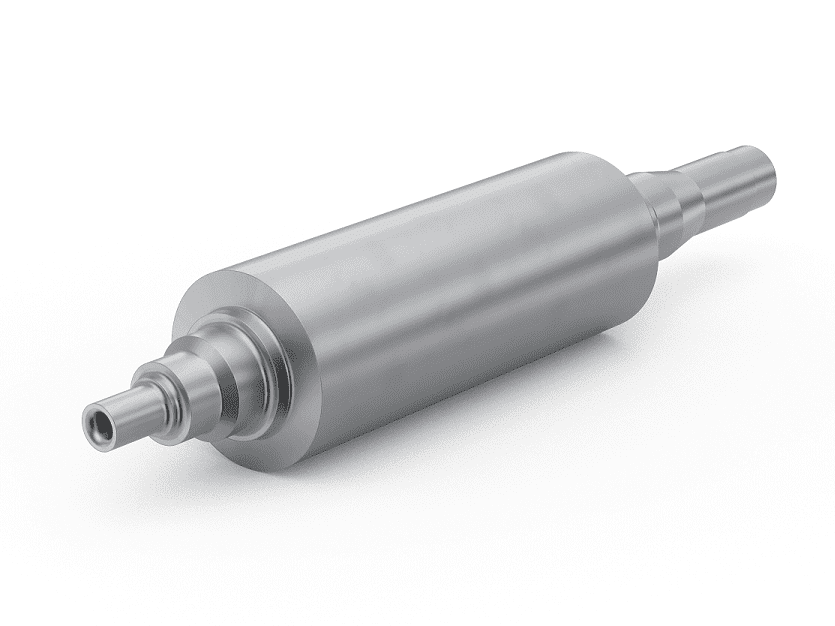

The VSTR 250, 500 and 750 series, on the other hand, produce precise tubes and hollow bodies. Advantages of the VSTR (vertical flow-forming) series – tubes & gearing components:

- High stability.

- Low material usage.

- Minimal/no post-processing.